It’s that time of the year again, and your feed has been inundated with sales. And if you’ve looking up for new furniture pieces, you’ve undoubtedly seen ads from Ikea.

What most people don’t know is that most of the photos used are 3D renderings created in-house by Ikea.

Why Ikea uses 3D Renderings over Photos

Before realistic 3D rendering techniques were available, Ikea spent a significant amount of time, cost to build each set for their photos. Given that they had a large product line, they would need to produce hundreds of sets, which would need to be tore down soon after.

Factoring in the number of people they would need to hire to help with set creation, photos for a catalogue would cost thousands and take months to produce.

As a result, Ikea decided to test the use of 3D renderings in their catalogues. They slowly inserted fake 3D renders of furniture in photos, and tested if anyone would notice.

No one did.

Currently, almost 80% of the photos from Ikea are 3D generated.

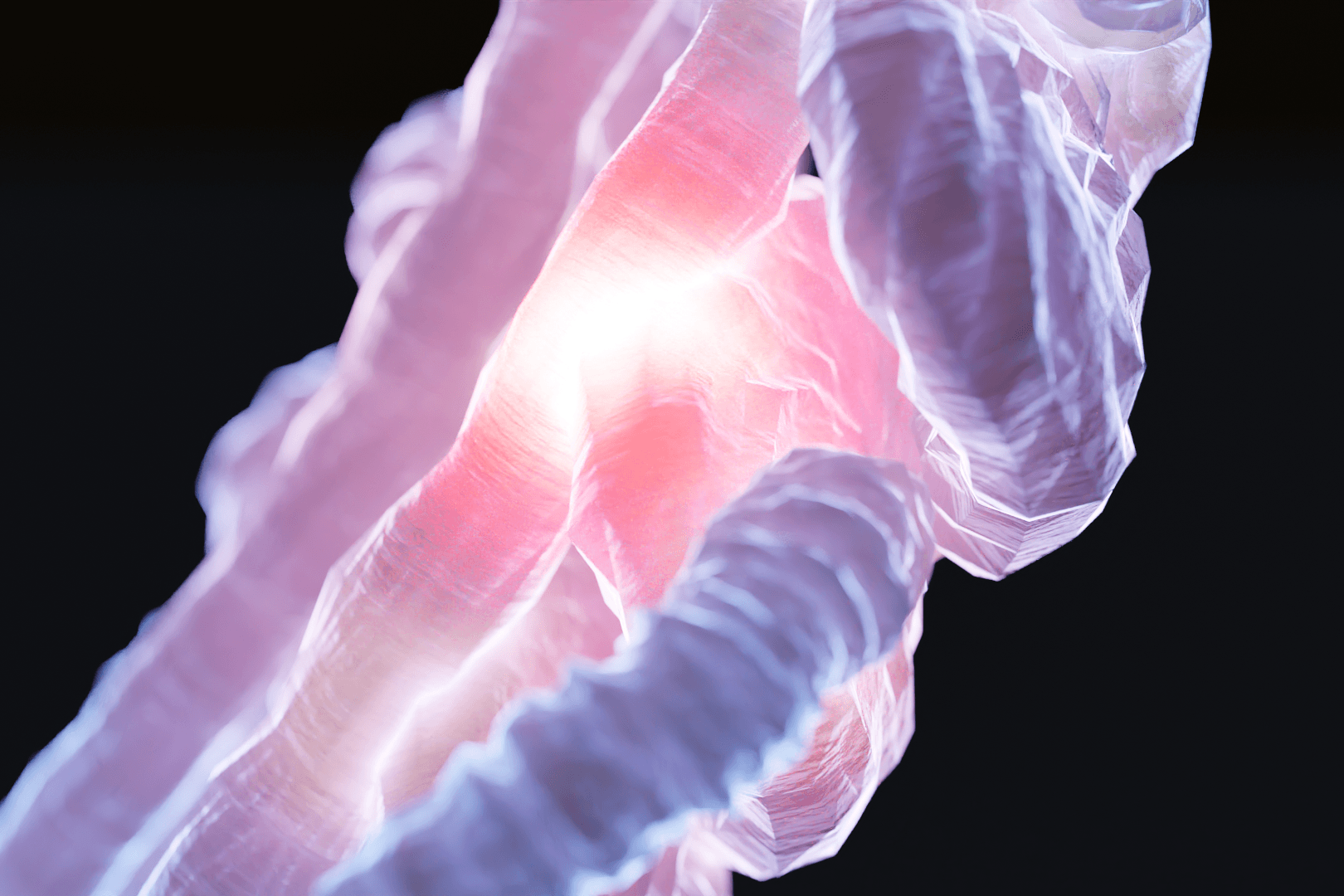

Why Medical Device Companies Should Use 3D Renders instead of Photos

Cost

Producing 3d renderings is significantly cheaper than the traditional photos. Moreover, assets such as product STL files can be saved and used for production at later dates or prototyping.

Traditional photos can only be used once, for a specific ad campaign, without the ability to be reused for other purposes.

Speed

Creating 3D renders is much faster and more efficient – and can be produced at any time of day (especially if product photos need to be placed in an outdoor scene).

New products, or even product features can even be tested to determine their level of demand.

Creative Control

Every single element of a scene can be modified until it’s perfect.

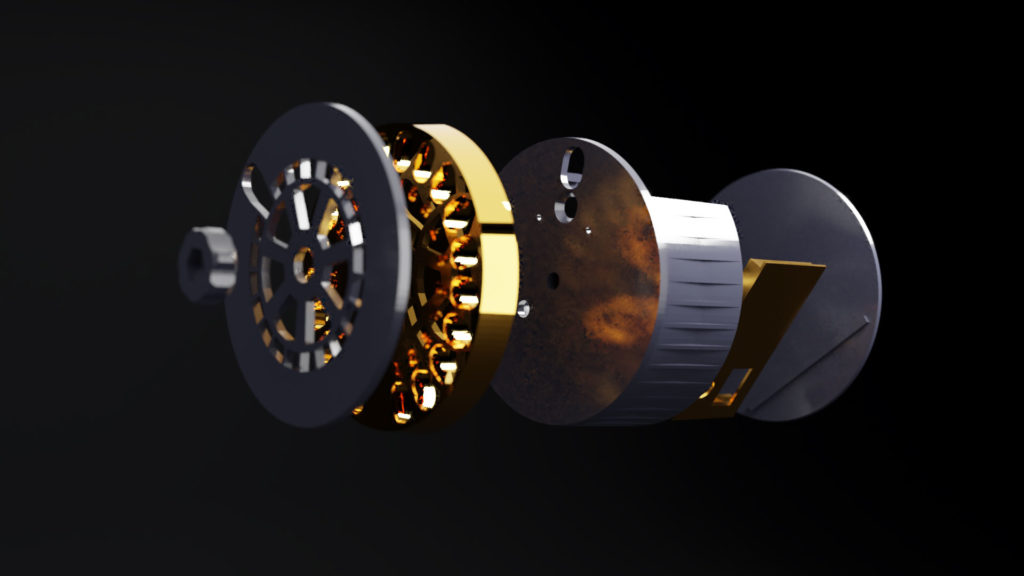

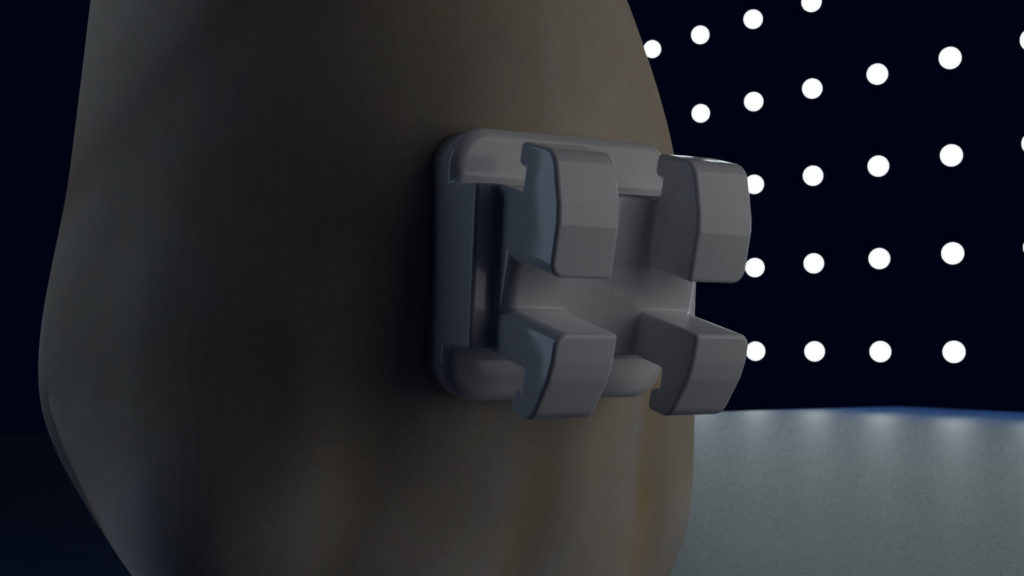

Since products can be altered in any way, products can be displayed in creative engaging ways to your target customer.

See what Apple has achieved with 3D renders:

With today’s technology, you can position your product amongst the best in the world.